Quality manufacturing starts with Statistical Process Control (SPC).

Reducing non-conformance begins with a solid quality planning process. Analyze and control production / manufacturing processes in real-time with the Statistical Process Control (SPC) Series to measurably reduce non-conformance issues. Create product configurations, collect and process data, analyze data for areas for improvement across your facility, even if there are hundreds of them across the country.

Take your SPC implementation to new levels of control and visibility as you integrate to gauges, scales, measurement equipment, optical comparators, CMMs, and more. The SPC Series was built for quality professionals who insist that SPC be deployed as close to the process as possible to assure rapid response to changes in process behavior. It collects, analyzes, distributes and maintains process control data, giving you control and visibility like never before.

The SPC Series instantly converts raw data into meaningful results by drawing on all the chart types you expect to find in an SPC software product. The charts include X-bar/R, X-bar/S, median and individuals with moving range, histograms, Pareto, P, C, U and nP. It also provides summary statistics that include all the process and capability statistics, measurement of skewness, kurtosis and chi square as well as providing for normal and non-normal distributions.

SPC Administrator

SPC Administrator allows Quality Engineers to create a Product Configuration that implements all aspects of your SPC strategy and measure them against your quality targets (Cpk, 6 Sigma, etc.):

- Product Characteristics – Identify all or only the critical characteristics and specifications for measurement.

- Process – Define your process and the locations where measurements will be made.

- Traceability – Assign trace topics to the product, process step, location, as needed to isolate and track the factors affecting process performance.

- Statistical Methods – Select from standard testing methods or define your own.

- Data Collection – Control the way data is collected choosing input method (manual or from an external device) and defining sampling sizes and frequencies and data entry sequence and approval steps.

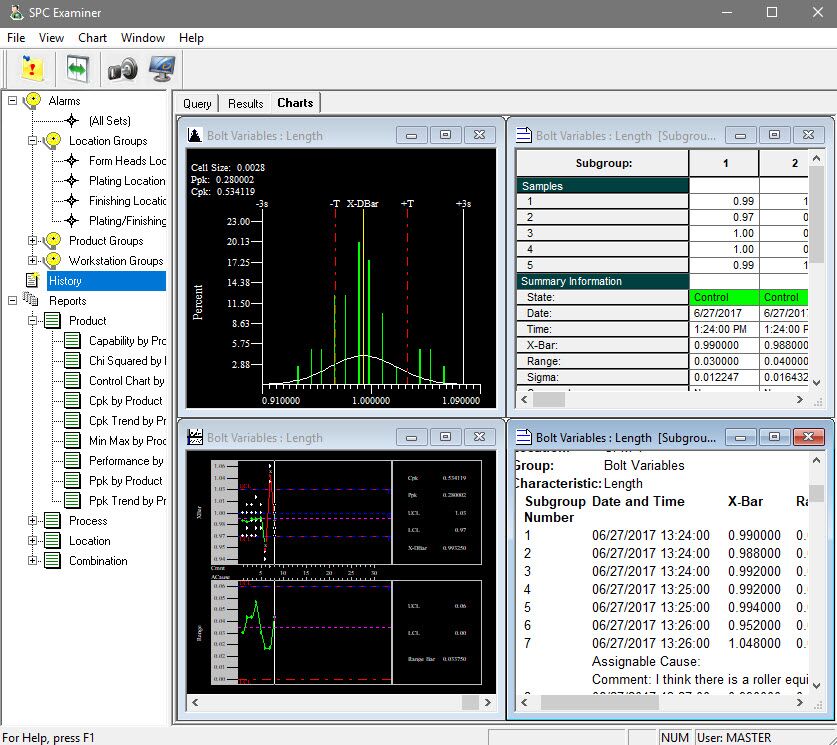

SPC Examiner

SPC Examiner

SPC Examiner provides powerful tools to make analysis easier. Alarms alert team members when a process has moved out of the previously defined acceptable limits, allowing everyone involved to be aware of problems and take action quickly. Your Quality Engineering department has access to both active and historical data sets, trend analysis and the ability to slice and dice this information using a rich set of charts and reports.

SPC Examiner also allows access to all data being collected anywhere within your system – meaning your access is not limited to the data collection workstation. Having anywhere-access to your data saves time and gives you full control of production processes.

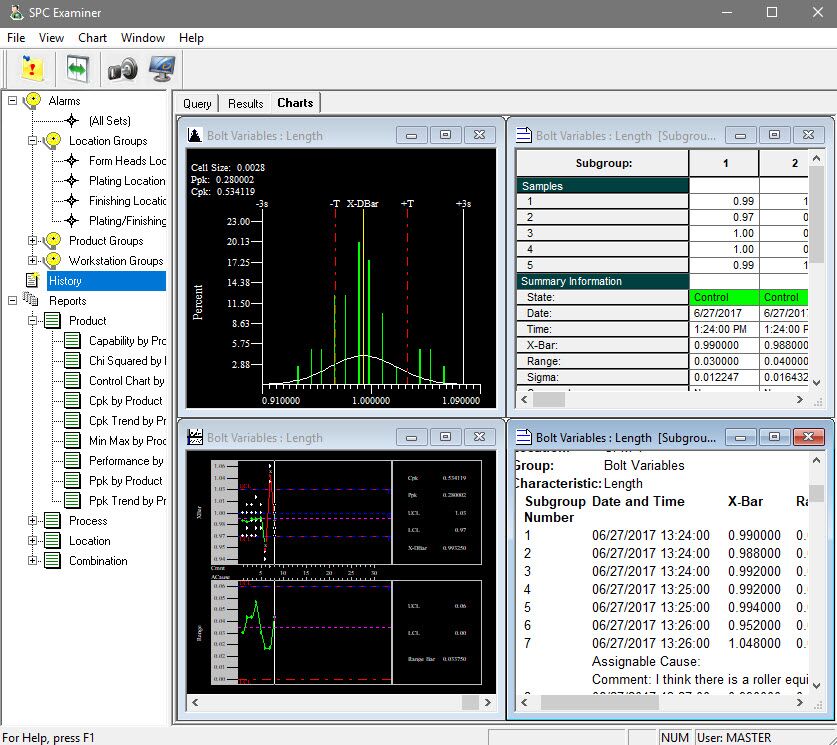

SPC Examiner

SPC Examiner provides powerful tools to make analysis easier. Alarms alert team members when a process has moved out of the previously defined acceptable limits, allowing everyone involved to be aware of problems and take action quickly. Your Quality Engineering department has access to both active and historical data sets, trend analysis and the ability to slice and dice this information using a rich set of charts and reports.

SPC Examiner also allows access to all data being collected anywhere within your system – meaning your access is not limited to the data collection workstation. Having anywhere-access to your data saves time and gives you full control of production processes.

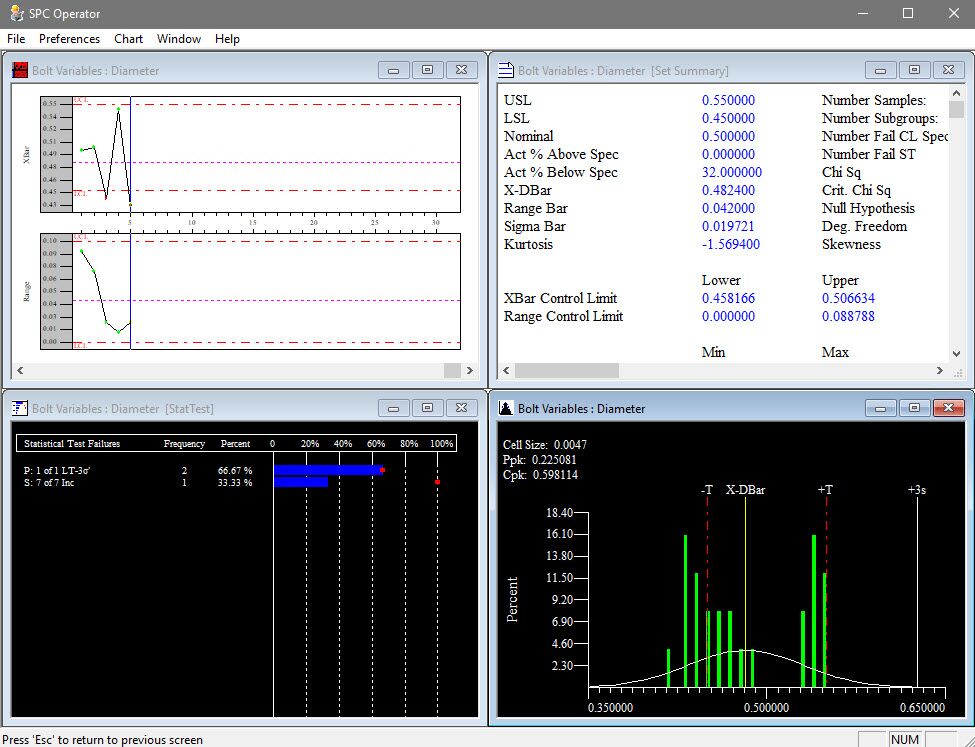

SPC Operator

The SPC Operator module gives you the information and tools to make decisions that improve product quality. Data collection and analysis are delivered where your products are actually produced. The user interface is especially designed for ease of use, even on the factory floor. Control charts, histograms, and Pareto charts are all available for the operators to review the current process and look for problems in your process before they result in bad parts.

The SPC Operator module gives you the information and tools to make decisions that improve product quality. Data collection and analysis are delivered where your products are actually produced. The user interface is especially designed for ease of use, even on the factory floor. Control charts, histograms, and Pareto charts are all available for the operators to review the current process and look for problems in your process before they result in bad parts.

Product configurations that take advantage of our automated data collection methods, eliminating the need for manual measurement entry, can also be initiated and monitored. Operators can see all active sets for their data collection locations, color coded to indicate the last subgroup's performance against the selected statistical tests.

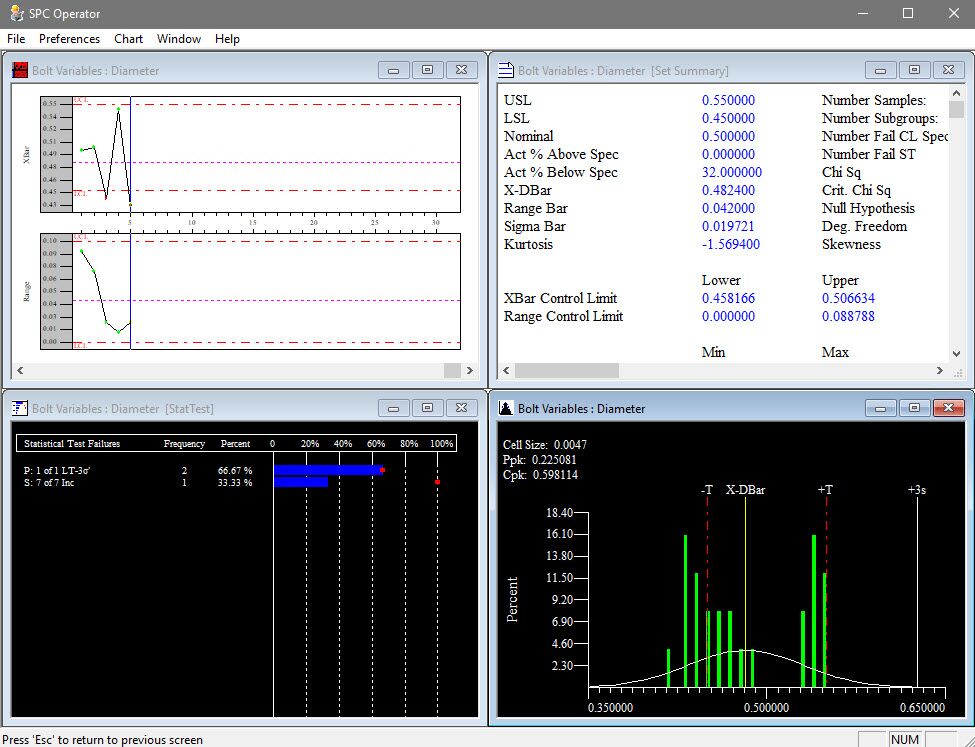

SPC Operator

The SPC Operator module gives you the information and tools to make decisions that improve product quality. Data collection and analysis are delivered where your products are actually produced. The user interface is especially designed for ease of use, even on the factory floor. Control charts, histograms, and Pareto charts are all available for the operators to review the current process and look for problems in your process before they result in bad parts.

Product configurations that take advantage of our automated data collection methods, eliminating the need for manual measurement entry, can also be initiated and monitored. Operators can see all active sets for their data collection locations, color coded to indicate the last subgroup's performance against the selected statistical tests.

Data Collection

Implementing automated data collection yields immediate results to your SPC program by eliminating the potential for data entry errors and delays, and increasing the amount of information that can be collected. The net result is better analysis, more time to identify improvements, and a process that is both more capable and in control.

Waypoint Global’s Custom Data Collection Services can offer solutions to your specific data collection needs quickly and cost effectively. Waypoint Global has been developing successful integration to data collection devices for over 20 years. The SPC Series API’s have enabled the development of a Data Collection Engine (DCE) toolkit, along with a powerful, proprietary scripting language, that means many solutions can be developed at the customer site within hours.

Below is a list of some of the device drivers already developed by our Custom Data Services Professionals:

- CMMs (Sheffield, Zeiss, Brown & Sharp)

- Weigh scales (Mettler, Sartorius, Ohaus, Doran)

- PLCs (Allen Bradley, GE, Modicon)

- Vision Systems (Allen Bradley, Cognex)

- Optical Comparaters (OGP SmartCheck, QuadraChek)

- Fixtured Gages (Mahr, Kurt, Etamic, Adcole)

- Databases (Access)

- Gagemux gage interface